ADVANTECH SOLUTIONS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ADVANTECH SOLUTIONS

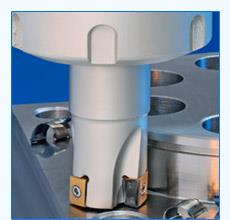

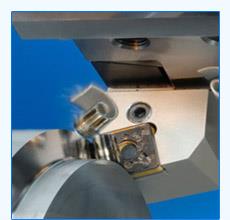

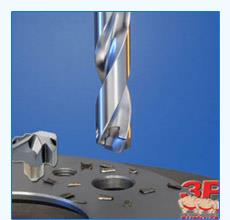

Turning Cutting Tools

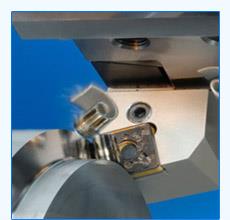

ISO standard tools perform most of the industry's chip removal. The applications range from finishing to roughing. As a full-line supplier of metalworking tools, ISCAR naturally provides the full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape. These semi-triangular turning inserts used for axial and face turning, feature three 80° corner cutting edges. They replace the rhombic inserts that had only two cutting edges, thus saving production time and cost while maximizing insert life. ISCAR offers a variety of unique chipformer and grade combinations that provide solutions to most of modern industry's machining needs.

ISCAR is launching a completely new line of external and internal tools as well as large size inserts for the heavy duty applications, called SUMOTURN. Heavy duty turning applications feature relatively large depths of cut, high feed rates and rough, non-uniform surfaces to be machined. These applications require both tough carbide grades and specifically designed chipformers. The recently introduced SUMO TEC carbide grades enable ISCAR to cope better with heavy duty turning. The new tools expand the range of ISCAR tools for rough turning applications. Lever Lock tools are recommended for large depth of cut and interrupted cut applications

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.